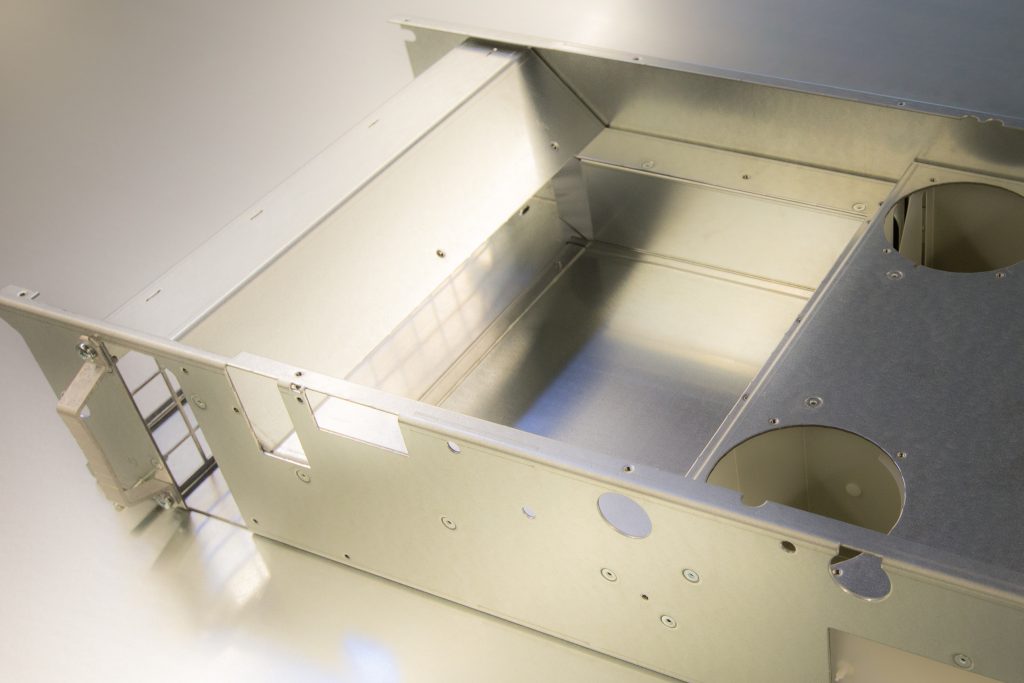

Assembly methods are, among others, riveting and bushing, welding and mounting.

In most cases, our customers require that their products are as much finished as possible, and we are only happy to process them as much as we can.

Riveting allows us to join items in a conventional way with pop-rivets, using Tox fastening method or similar is an alternative solution.

Every year we install millions of rivets in our products. We use both hydraulic as well as servo presses. Some of the riveting presses are equipped with automated rivet feeders and tool change cases.

In welding, we mostly use spot welding in our production. We operate both traditional spot-welding machines as well as smart welding machines with adaptive control. In addition to those, we also have resistance projection welding equipment. Other welding techniques are MIG and TIG welding. Laser welding has now been outsourced to partners. Along with the increase of production volumes, different welding phases can be automatized.

At the final assembly phase, products are integrated with each other, and different components are mounted together. We install electrical and electronic components in the products, as well as seals, rubber parts, fasteners and other mechanical components. Typically, we produce pre-assemblies that are used by our customer to make their own final products. We can also manufacture, test and pack products ready to be dispatched directly to the end user.