Seger Oy uses presses, CNC turret presses and a combi laser to do punching and produce pre-forms.

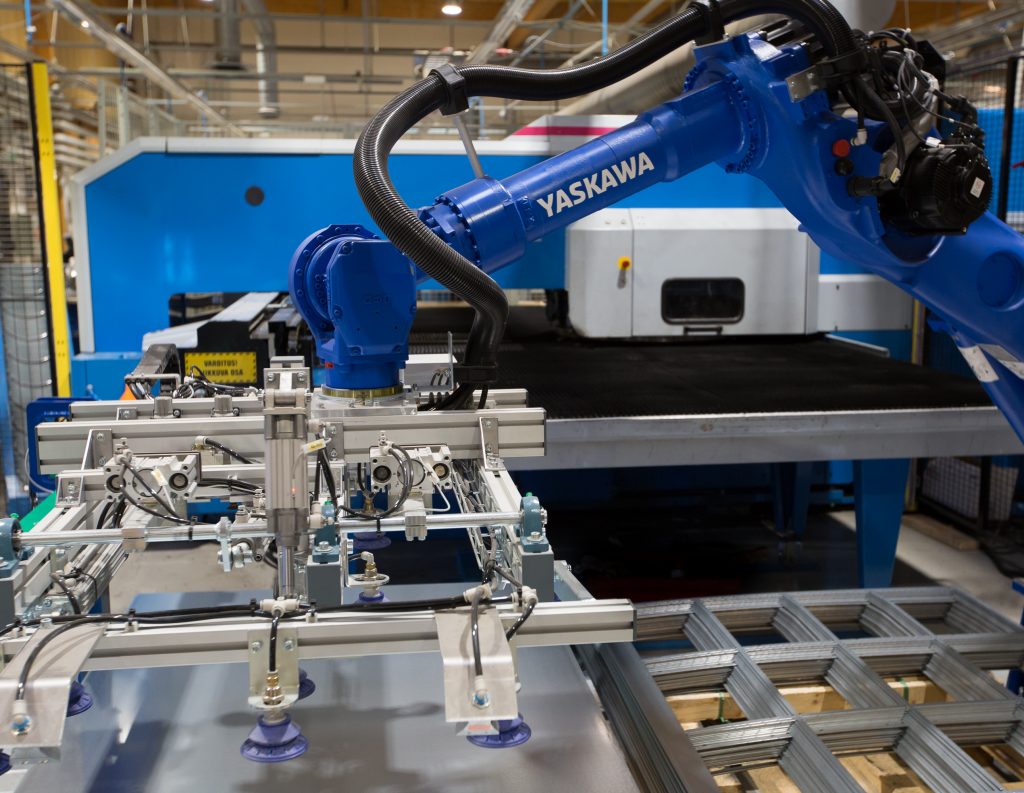

Some of the CNC turret presses are equipped with automatic feeding and unloading systems, in some machines these functions are handled by a robot. Moreover, using automation makes it possible to create an unmanned production environment. The maximum sheet dimensions are 1500 mm x 3000 mm, and the maximum material thickness is 6 mm. CNC turret presses are replaced when needed, and new production equipment is purchased when needed to satisfy the required capacity and customer demands.

CNC turret presses are convenient tools to make prototypes and pre-series for products. Production of smaller volumes using CNC turret presses will also remain an efficient solution. When the production volumes increase, it is time to start making pre-forms with presses, using either simpler cutting dies or progressive tooling which combine a number of different production phases. Generally, CNC turret presses offer an efficient solution for pre-form production if the annual volume remains below 10,000 pcs. As the volume grows, it is worth starting to use other techniques.