Products of our customers have many features that require special production processes. The most common processes are threading, grinding and surface treatment.

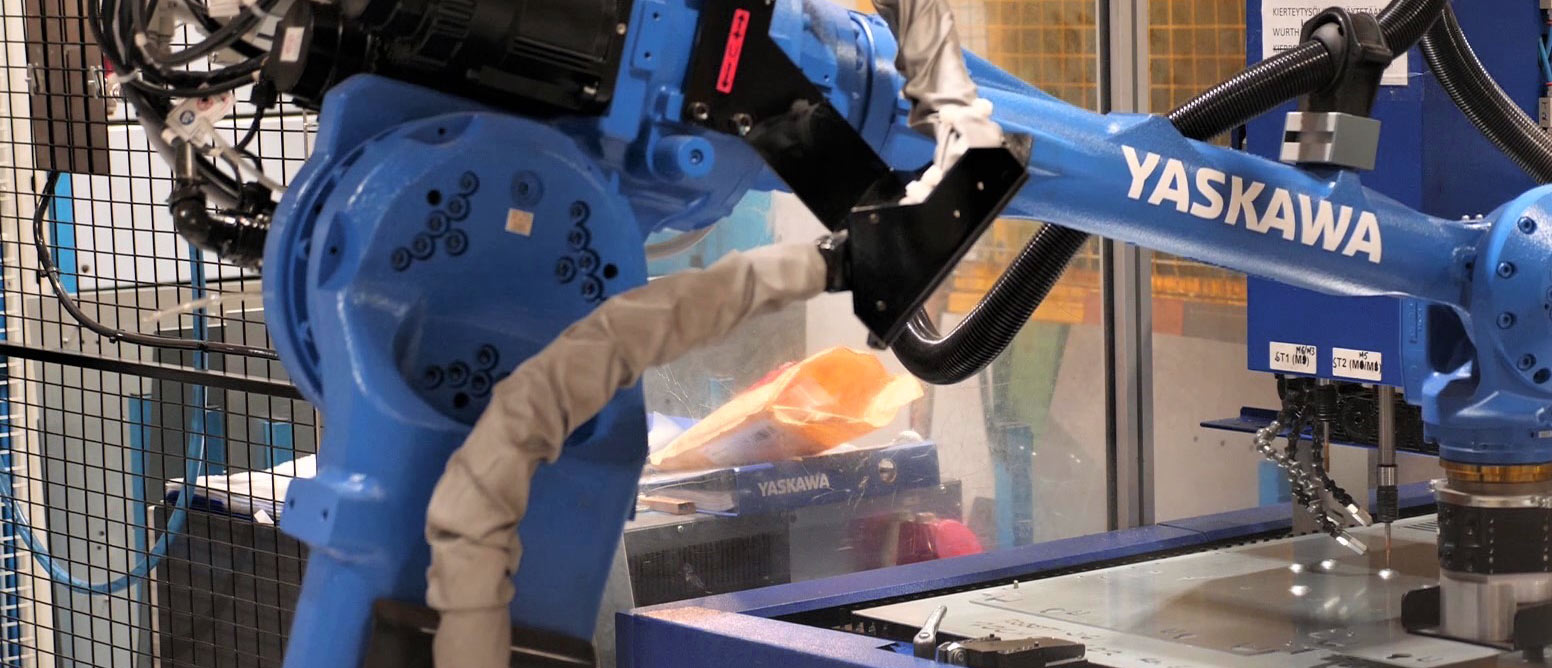

A large number of products we manufacture have threads. We do threading with various methods. In our CNC turret presses, we use threading units, we also have a robotized CNC threading cell, and we can provide small scale threading manually, using threading tools with linear control machinery. Moreover, threading can also be integrated into progressive tooling. By automating the process, we have reached an excellent level of quality in threading.

Various products we make are used in final products where even the slightest sharpness of edges can cause risks for people who use them. For many products, deburring and grinding of cut surfaces are critical requirements. For that purpose, we have grinding lines that produce single- or double-side grinding without damaging the shape of the part.

Surface treatment we have outsourced to our partners who are specialised in these processes. Our partners are located nearby, along a route we drive daily. The most common surface treatment we use are tin plating and silver plating of copper products, but we can also provide other electrolytic coating and painting options.