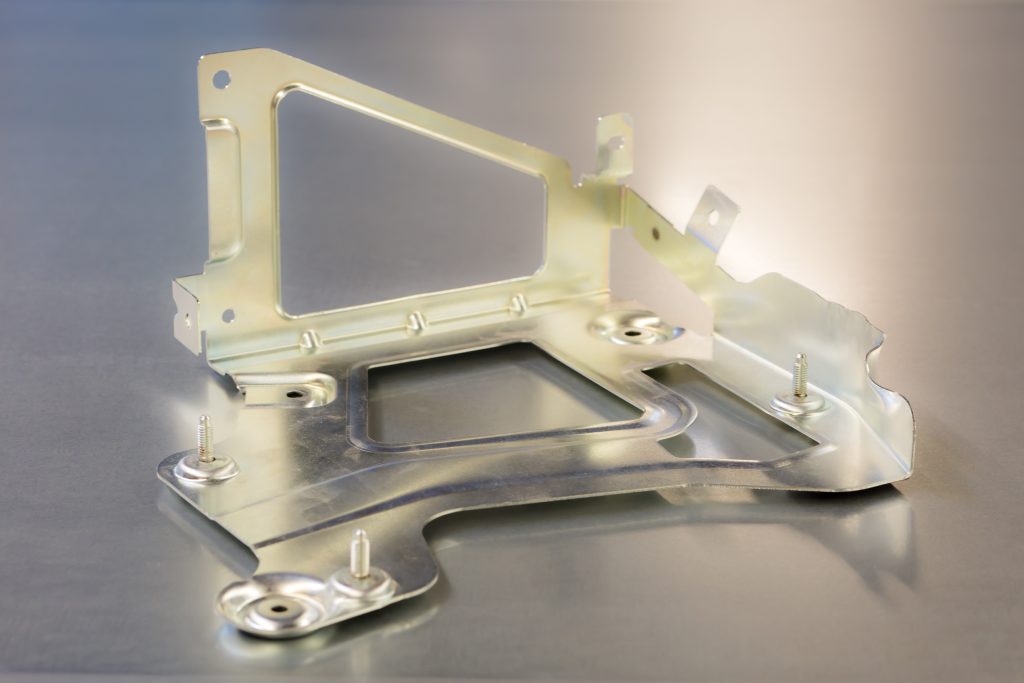

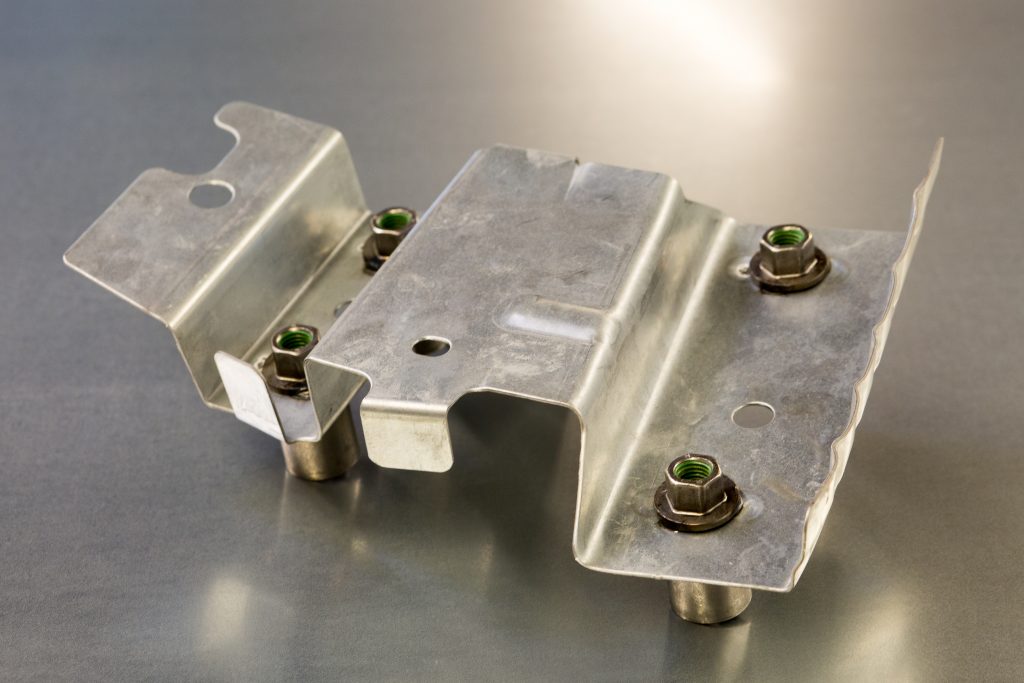

Seger Oy’s special expertise lies in applying pressing techniques in manufacturing of various products.

The company has its roots in production of sheet metal components for automobile industry using press tools, and this background has guided us towards finding more efficient and high-quality production techniques for customers among various industries.

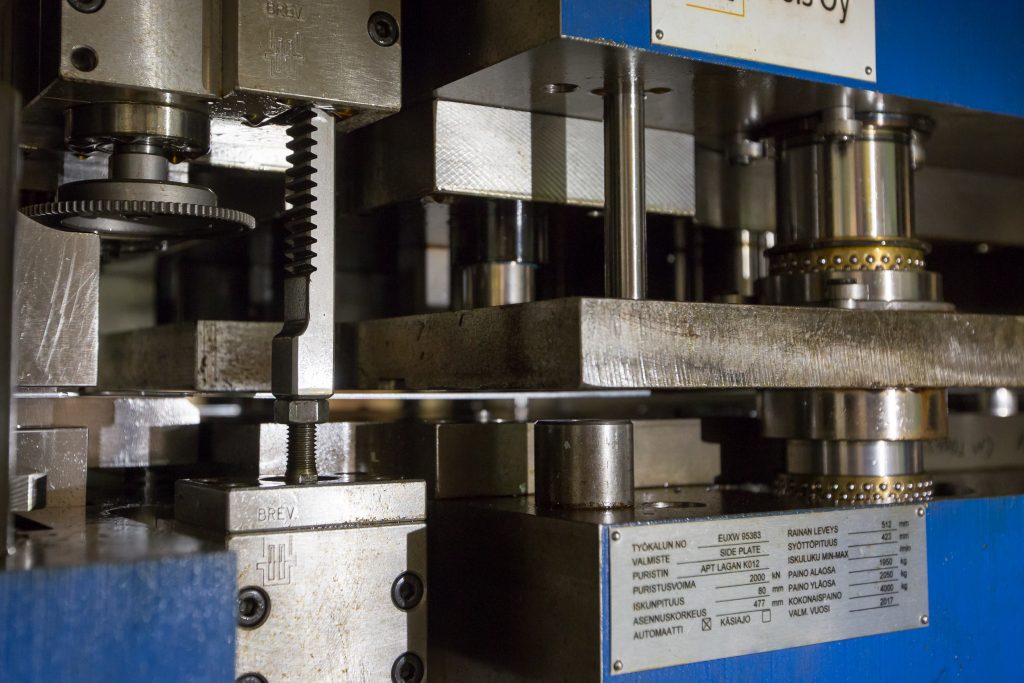

Seger Oy has a wide selection of eccentric presses and hydraulic presses. Our press shop has eccentric presses ranging from 50 to 600 tons. Most of the presses feature line equipment, including automatic lubrication and band control. Some of our hydraulic presses are fitted with line equipment for progressive tooling, but most of them are multifunctional machines used for deep drawing. The capacity of hydraulic presses ranges from 100 to 600 tons.

Seger Oy offers customers a wide selection of different options for manufacturing their products. Change from production with CNC machinery to pressing tools can be handled smoothly during the product’s life cycle. This makes it possible to invest in tools only when there is actual need for that and it is clear that product volumes are growing. For instance, if investments into bending tools are made at the start of the product’s life cycle, it is possible to shift from CNC stamping to using hard bending tools, while pre-forms can be produced using lasers or turret presses. Along with increasing production volumes, it is possible to invest in various press tools or progressive tools for pre-forms or finished products.