Bending is handled by CNC controlled bending machines or with presses equipped with bending tools.

Bending is an excellent choice when volumes are small or medium-sized, as well as when the geometry of the item does not require deep drawing. For bending Seger uses manual machinery with the capacity between 22 to 125 tons and maximum table length of 3000 mm.

Bending is automatized by robotising press brakes. Robot cells programming is handled by a remote programming software. This has considerably reduced the set-up time required to manufacture the products, even producing smaller volumes in robot cells is reasonable.

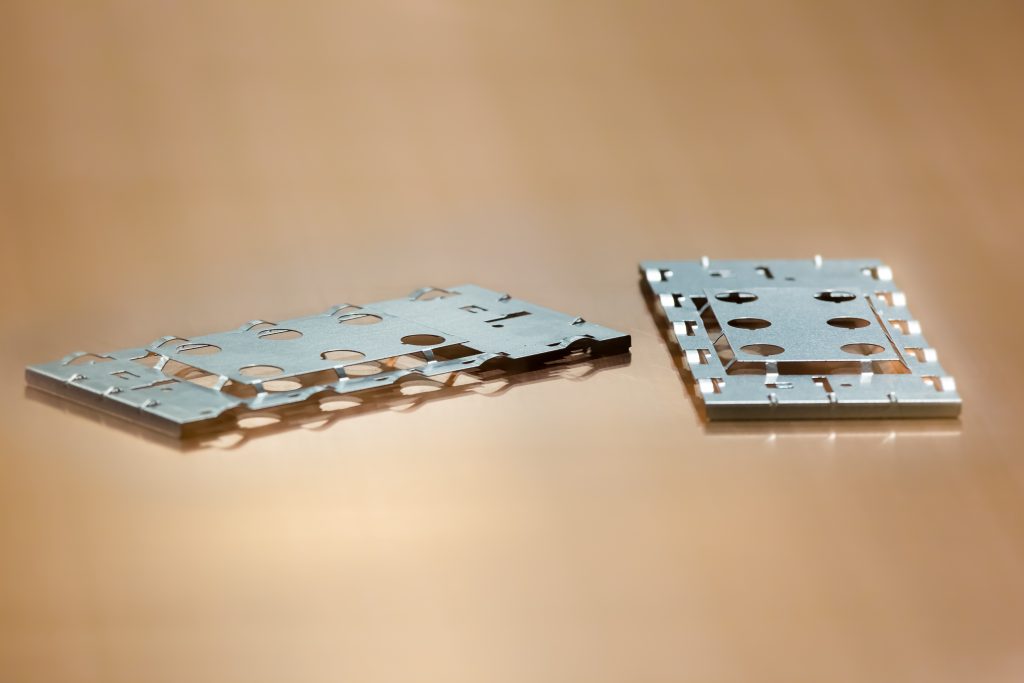

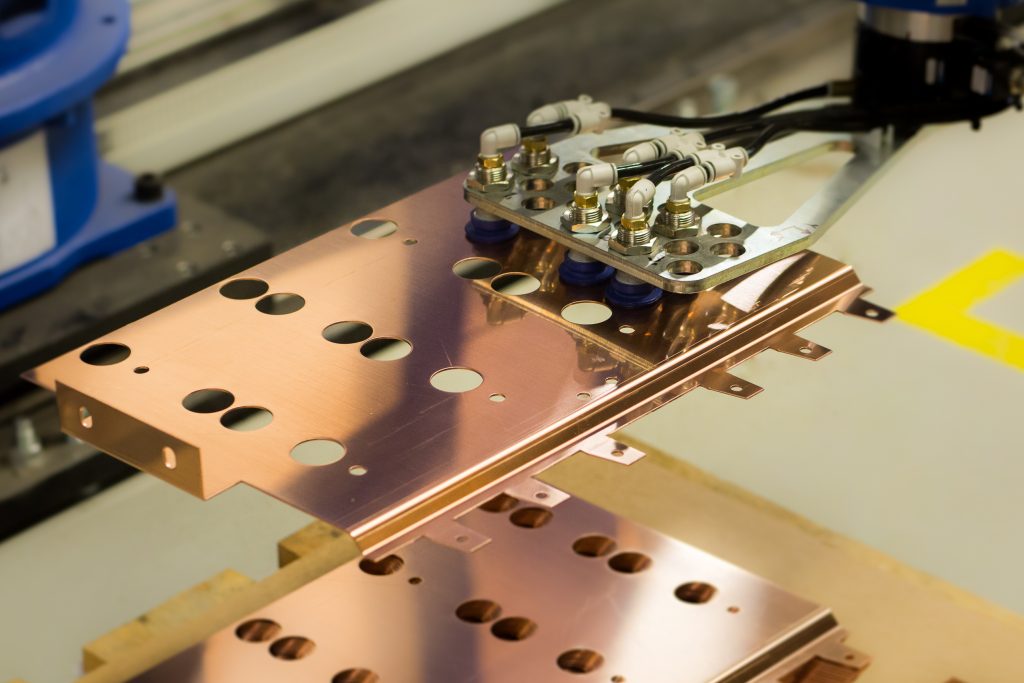

When production volumes increase, it is time to move production to hard tools and bending processes to presses. At the same time when dies are given their desired forms, other work phases can be integrated into tools. This provides additional benefits, reduces costs, and shortens the tooling’s payback time.